Contents

1.4 Summary of Construction Works

1.5 Summary of EM&A Programme Requirements

2.3.2 Maintenance and Calibration

2.4 Summary of Monitoring Results

3.3.2 Maintenance and Calibration

3.4 Summary of Monitoring Results

5.3 Marine Sediment Management

6 Chinese White Dolphin Monitoring

6.2 CWD Monitoring Methodology

6.2.1 Small Vessel Line-transect Survey

6.3 Monitoring Results and Observations

6.3.1 Small Vessel Line-transect Survey

6.4 Site Audit for CWD-related Mitigation Measures

6.5 Timing of reporting CWD Monitoring Results

7 Environmental Site Inspection and Audit

7.1 Environmental Site Inspection

7.2 Landscape and Visual Mitigation Measures

7.3 Land Contamination Assessment

7.4 Audit of SkyPier High Speed Ferries

7.5 Audit of Construction and Associated Vessels

7.6 Implementation of Dolphin Exclusion Zone

7.7 Status of Submissions under Environmental Permits

7.8 Compliance with Other Statutory Environmental Requirements

7.9 Analysis and Interpretation of Complaints, Notification of Summons and Status of Prosecutions

7.9.2 Notifications of Summons or Status of Prosecution

8 Future Key Issues and Other EIA & EM&A Issues

8.1 Construction Programme for the Coming Reporting Period

8.2 Key Environmental Issues for the Coming Reporting Period

8.2.1 Construction Activities in the Coming Reporting Period

8.3 Monitoring Schedule for the Coming Reporting Period

8.4 Review of the Key Assumptions Adopted in the EIA Report

9 Conclusion and Recommendation

Table 1.1: Contact Information of Key Personnel

Table 1.2: Summary of Status of All Environmental Aspects under the Updated EM&A Manual

Table 2.1: Locations of Impact Air Quality Monitoring Stations

Table 2.2: Action and Limit Levels of Air Quality Monitoring

Table 2.3: Air Quality Monitoring Equipment

Table 2.4: Summary of Air Quality Monitoring Results

Table 3.1: Locations of Impact Noise Monitoring Stations

Table 3.2: Action and Limit Levels for Noise Monitoring

Table 3.3: Noise Monitoring Equipment

Table 3.4: Summary of Construction Noise Monitoring Results

Table 5.1: Action and Limit Levels for Construction Waste

Table 5.2: Construction Waste Statistics

Table 6.1: Coordinates of Transect Lines in NEL, NWL, AW, WL and SWL Survey Areas

Table 6.2: Summary of Photo Identification

Table 7.1: Landscape and Visual – Construction Phase Audit Summary

Table 7.2: Examples of Landscape and Visual Mitigation Measures in the Reporting Period

Table 7.3: Monitoring Programme for Landscape and Visual

Table 7.4: Event and Action Plan for Landscape and Visual

Table 7.6: Summary of the Transplanted Trees Updated in the Reporting Period

Table 7.7: Summary of Key Audit Findings against the SkyPier Plan

Table 7.8: Status of Submissions under Environmental Permit

Appendices

|

Environmental Mitigation Implementation Schedule (EMIS) for Construction Phase |

|

|

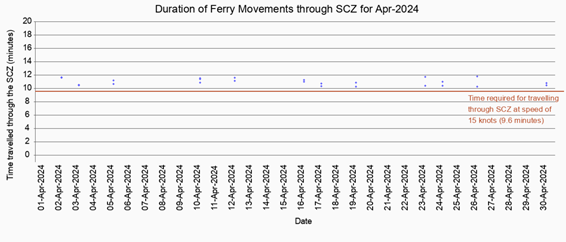

Data of SkyPier HSF Movements to/from Macau (between 1 and 30 April 2024) |

Abbreviations

|

3RS |

Three-Runway System |

|

AAHK |

Airport Authority Hong Kong |

|

AECOM |

AECOM Asia Company Limited |

|

AFCD |

Agriculture, Fisheries and Conservation Department |

|

AIS |

Automatic Information System |

|

ANI |

Encounter Rate of Number of Dolphins |

|

APM |

Automated People Mover |

|

AW |

Airport West |

|

BHS |

Baggage Handling System |

|

C&D |

Construction and Demolition |

|

CAP |

Contamination Assessment Plan |

|

CAR |

Contamination Assessment Report |

|

CTCC |

Construction Traffic Control Centre |

|

CWD |

Chinese White Dolphin |

|

DCM |

Deep Cement Mixing |

|

DEZ |

Dolphin Exclusion Zone |

|

DO |

Dissolved Oxygen |

|

EIA |

Environmental Impact Assessment |

|

EM&A |

Environmental Monitoring & Audit |

|

EP |

Environmental Permit |

|

EPD |

Environmental Protection Department |

|

EPSS |

Emergency Power Supply Systems |

|

ET |

Environmental Team |

|

FCZ |

Fish Culture Zone |

|

HKBCF |

Hong Kong-Zhuhai-Macao Bridge Hong Kong Boundary Crossing Facilities |

|

HKIA |

Hong Kong International Airport |

|

HOKLAS |

Hong Kong Laboratory Accreditation Scheme |

|

HSF |

High Speed Ferry |

|

HVS |

High Volume Sampler |

|

I-2RS |

Interim Two-Runway System |

|

IEC |

Independent Environmental Checker |

|

LKC |

Lung Kwu Chau |

|

MMHK |

Mott MacDonald Hong Kong Limited |

|

MMWP |

Marine Mammal Watching Plan |

|

MSS |

Maritime Surveillance System |

|

MTRMP-CAV |

Marine Travel Routes and Management Plan for Construction and Associated Vessel |

|

NEL |

Northeast Lantau |

|

NWL |

Northwest Lantau |

|

PAM |

Passive Acoustic Monitoring |

|

PM |

Project Manager |

|

SC |

Sha Chau |

|

SCZ |

Speed Control Zone |

|

SCLKCMP |

Sha Chau and Lung Kwu Chau Marine Park |

|

SS |

Suspended Solids |

|

SSSI |

Site of Special Scientific Interest |

|

STG |

Encounter Rate of Number of Dolphin Sightings |

|

SWL |

Southwest Lantau |

|

T2 |

Terminal 2 |

|

The Project |

The Expansion of Hong Kong International Airport into a Three-Runway System |

|

The SkyPier Plan |

Marine Travel Routes and Management Plan for High Speed Ferries of SkyPier |

|

The Manual |

The Updated EM&A Manual |

|

TSP |

Total Suspended Particulates |

|

WL |

West Lantau |

|

WMP |

Waste Management Plan |

The “Expansion of Hong Kong International Airport into a Three-Runway System” (the Project) serves to meet the future air traffic demands at Hong Kong International Airport (HKIA). On 7 November 2014, the Environmental Impact Assessment (EIA) Report (Register No.: AEIAR-185/2014) for the Project was approved and an Environmental Permit (EP) (Permit No.: EP-489/2014) was issued for the construction and operation of the Project.

Airport Authority Hong Kong (AAHK) commissioned Mott MacDonald Hong Kong Limited (MMHK) to undertake the role of Environmental Team (ET) for carrying out the Environmental Monitoring & Audit (EM&A) works during the construction phase of the Project in accordance with the Updated EM&A Manual (the Manual).

This is the 100th Construction Phase Monthly EM&A Report for the Project which summarises the monitoring results and audit findings of the EM&A programme during the reporting period from 1 to 30 April 2024.

During the reporting period, the project is in the Interim Two-Runway System (I-2RS) stage, in which the new North Runway and the associated taxiway and facilities were operated together with the South Runway and existing airport facilities, with the Centre Runway closed down for modification works.

Key Activities in the Reporting Period

The key activities of the Project carried out in the reporting period are located in reclamation areas and existing airport island respectively. Works in the reclamation areas included land improvement works, filling works, pavement works, concourse superstructure works, tunnel works for Automated People Mover (APM) and Baggage Handling System (BHS) and associated works. Land-based works on existing airport island involved Terminal 2 (T2) expansion works, modification and tunnel works for APM and BHS, utilities works, road and drainage works, excavation works, and 132kV cable laying works.

EM&A Activities Conducted in the Reporting Period

The monthly EM&A programme was undertaken in accordance with the Manual of the Project. Summary of the monitoring activities during this reporting period is presented as below:

|

Monitoring Activities |

Number of Sessions |

|

1-hour Total Suspended Particulates (TSP) air quality monitoring |

30 |

|

Noise monitoring |

16 |

|

Vessel line-transect surveys for post-construction phase Chinese White Dolphin (CWD) monitoring |

2 |

Environmental auditing works, including weekly site inspections, ad-hoc site inspections of construction works conducted by the ET and bi-weekly site inspections conducted by the Independent Environmental Checker (IEC), audit of SkyPier High Speed Ferries (HSF), audit of construction and associated vessels were conducted in the reporting period. Based on the information including ET’s observations, records of Maritime Surveillance System (MSS), and contractors’ site records, it is noted that environmental pollution control and mitigation measures were properly implemented and construction activities of the Project in the reporting period did not introduce adverse impacts to the sensitive receivers.

A post-construction phase CWD monitoring by vessel line transect survey was conducted following the same methodology as adopted in construction phase monitoring.

Snapshots of EM&A Activities in the Reporting Period

|

|

|

|

|

Impact Air Quality Monitoring conducted by ET at Tin Sum Village House |

On-site Checking of Wastewater Treatment Facility by ET |

On-site Checking of Non-road Mobile Machinery (NRMM) Label conducted by ET |

Results of Impact Monitoring

The monitoring works for construction dust, construction noise, construction waste and landscape & visual were conducted during the reporting period in accordance with the Updated EM&A Manual.

Monitoring results of construction dust, construction noise, and construction waste did not trigger the corresponding Action and Limit Levels in the reporting period.

Summary of Upcoming Key Issues

Reclamation Works:

Contract 3206 Main Reclamation Works

● Filling materials delivery; and

● Marine sediment treatment works.

Airfield Works:

Contract 3302 Eastern Vehicular Tunnel Advance Works

● Underground utilities works.

Contract 3305 Airfield Ground Lighting System

● Enhanced vehicular warning light hardware installation;

● Power supply system installation; and

● Cable containment installation.

Contract 3310 North Runway Modification Works

● Underground utilities works;

● Construction of vehicular tunnels;

● Pavement works for runway;

● Land improvement works;

● Landscape works; and

● Architectural, builder's work and finishing works.

Terminal 2 Concourse and Apron Works:

Contract 3403 New Integrated Airport Centres Building and Civil Works

● Electrical and mechanical works; and

● Testing and commissioning works.

Contract 3404 Integrated Airport Control System

● Electrical and mechanical works.

Contract 3405 Third Runway Concourse Foundation and Substructure Works

● Backfilling works; and

● Drainage works

Contract 3408 Third Runway Concourse and Apron Works

● Building services and architectural, builder's work and finishing works;

● Fuel pipe installation works;

● Utilities works;

● Erection works for concrete batching plant;

● Reinforced concrete works;

● Backfilling works; and

● Cable laying works.

Terminal 2 Expansion:

Contract 3508 Terminal 2 Expansion Works

● Pier, deck and parapet construction;

● Drainage construction and utilities works;

● Roof works;

● Crossroad duct laying works;

● Construction of beams and columns;

● Electrical and mechanical works; and

● Architectural, builder's work and finishing works.

Automated People Mover and Baggage Handling System:

Contract 3601 New Automated People Mover System (TRC Line)

● Guide beam installation.

Contract 3602 Existing APM System Modification Works

● Concrete plinth and track plinth construction;

● New Swing Gates installation works; and

● Cabling works.

Contract 3603 Baggage Handling System (BHS)

● BHS and fire service installation;

● Electrical and mechanical component and lighting system installation;

● Steel work and electrical installation; and

● Conveyor and electrical installation.

Airport Support Infrastructure:

Contract 3801 APM and BHS Tunnels on Existing Airport Island

● Backfilling works;

● Road reinstatement works; and

● Drainage and underground utilities reinstatement works.

Contract 3802 APM and BHS Tunnels and Related Works

● Excavation and lateral supports;

● Box culvert construction and superstructure works;

● APM and BHS Tunnel construction;

● Reinforced concrete works;

● Architectural, builder's work and finishing works; and

● Marine sediment treatment works.

Contract 3804 East and Landside Fire Stations

● Site setup and formation works;

● Superstructure works and architectural, builder’s work and finishing works;

● Piles interface core and pile cap construction works;

● Electrical and mechanical works; and

● Underground utilities works.

Contract 3805 New Airport District Police Operational Base

● Bored pile works;

● Pile cap works; and

● Site formation works.

Construction Support:

Contract 3733 Emergency Repair Service

● Marine sediment treatment works.

Contract 3901A Concrete Batching Facility

● Operation of concrete batching plant and material conveyor belt.

Contract 3901B Concrete Batching Facility

● Operation of concrete batching plant and material conveyor belt.

Contract 3908 Quay Management Services

● Provision of services of site management and logistic control of 3RS quays; and

● Provision of flat top barge and vehicle delivery services between the launching point in Hong Kong and 3RS quays.

Contract 3913 Asphalt Batching Plant

● Operation of asphalt batching plant.

Utilities:

132kV Cable

● Cable trenching, cable laying, duct installation and backfilling.

Summary Table

The following table summarises the key findings of the EM&A programme during the reporting period:

|

Yes |

No |

Details |

Analysis / Recommendation / Remedial Actions |

|

|

Breach of Limit Level^ |

|

√ |

No breach of Limit Level was recorded. |

Nil |

|

Breach of Action Level^ |

|

√ |

No breach of Action Level was recorded. |

Nil |

|

Complaint Received |

|

√ |

In the previous reporting period, a complaint regarding construction dust at Airport North Interchange and South Perimeter Road was received on 15 March 2024. |

ET requested the relevant contractors to provide information regarding the complaint and replies indicated dust suppression measures were in place. During the ET’s site inspections, no dust related items were recorded. Nevertheless, the relevant contractors were reminded to continuously implement dust mitigation measures at their vehicular site exits and works areas adjacent to public roads. Hence, the case was considered closed. |

|

|

|

|

In the previous reporting period, a complaint regarding noise issue at Cheong Tat Road was received on 15 March 2024. |

ET requested the relevant contractor to provide information regarding the complaint and reply indicated noise control measures were implemented. During the ET’s site inspections, no noise nuisance issue was recorded. Nevertheless, the relevant contractor was reminded to continuously implement their current and enhanced noise mitigation measures. Hence, the case was considered closed. |

|

Notification of any summons and status of prosecutions |

|

√ |

No notification of summons nor prosecution was received. |

Nil |

|

Change that affect the EM&A |

|

√ |

There was no change to the construction works that may affect the EM&A. |

Nil |

Note:

^ Only triggering of Action or Limit Level found related to Project works is counted as Breach of Action or Limit Level.

1

Introduction

1.1

Background

On 7 November 2014, the Environmental Impact Assessment (EIA) Report (Register No.: AEIAR-185/2014) for the “Expansion of Hong Kong International Airport into a Three-Runway System” (the Project) was approved and an Environmental Permit (EP) (Permit No.: EP-489/2014) was issued for the construction and operation of the Project.

Airport Authority Hong Kong (AAHK) commissioned Mott MacDonald Hong Kong Limited (MMHK) to undertake the role of Environmental Team (ET) for carrying out the Environmental Monitoring & Audit (EM&A) works during the construction phase of the Project in accordance with the Updated EM&A Manual (the Manual) submitted under EP Condition 3.1[1]. AECOM Asia Company Limited (AECOM) was employed by AAHK as the Independent Environmental Checker (IEC) for the Project.

The Project covers the expansion of the existing airport into a three-runway system (3RS) with key project components comprising land formation of about 650 ha and all associated facilities and infrastructure including taxiways, aprons, aircraft stands, a passenger concourse, an expanded Terminal 2 (T2), all related airside and landside works and associated ancillary and supporting facilities. The submarine aviation fuel pipelines and submarine power cables also require diversion as part of the works.

Construction of the Project is to proceed in the general order of diversion of the submarine aviation fuel pipelines, diversion of the submarine power cables, land formation, and construction of infrastructure, followed by construction of superstructures.

The summary of construction works programme can be referred to Section 1.4.

1.2

Scope

of this Report

This is the 100th Construction Phase Monthly EM&A Report for the Project which summarises the key findings of the EM&A programme during the reporting period from 1 to 30 April 2024.

1.3

Project

Organisation

The Project’s organisation structure presented in Appendix B of the Construction Phase Monthly EM&A Report No.1 remained unchanged during the reporting period. Contact details of the key personnel are presented in Table 1.1.

Table 1.1: Contact Information of Key Personnel

|

Party |

Position |

Name |

Telephone |

|

Project Manager’s Representative (Airport Authority Hong Kong) |

Principal Manager, Environmental Compliance, Sustainability |

Lawrence Tsui |

2183 2734 |

|

Environmental Team (ET) (Mott MacDonald Hong Kong Limited) |

Environmental Team Leader |

Terence Kong |

2828 5919 |

|

Deputy Environmental Team Leaders |

Heidi Yu |

2828 5704 |

|

|

Ken Wong |

2828 5817 |

||

|

Independent Environmental Checker (IEC) (AECOM Asia Company Limited) |

Independent Environmental Checker |

Roy Man |

3729 0380 |

|

Deputy Independent Environmental Checker |

Jackel Law |

3856 5312 |

Reclamation Works:

|

Party |

Position |

Name |

Telephone |

|

Contract 3206 Main Reclamation Works (ZHEC-CCCC-CDC Joint Venture) |

Project Manager |

Alan Mong |

3763 1352 |

|

Environmental Officer |

Zhang Bin Wang |

3763 1525 |

Airfield Works:

|

Party |

Position |

Name |

Telephone |

|

Contract 3302 Eastern Vehicular Tunnel Advance Works (China Road and Bridge Corporation) |

Project Manager |

Dickey Yau |

5699 4503 |

|

Environmental Officer |

Dennis Ho |

5645 0563 |

|

|

Contract 3305 Airfield Ground Lighting System (ADB Safegate Hong Kong Limited) |

Project Manager |

Allam Al-Turk |

2944 9725 |

|

Environmental Officer |

Ivan Ting |

9222 9490 |

|

|

Contract 3306 Observation Facility Control System Supporting Interim 2RS and 3RS (Chinney Alliance Engineering Limited) |

Project Director |

Dennis Yam |

9551 9920 |

|

Environmental Officer |

Richard Liu |

9216 8990 |

|

|

Contract 3307 Fire Training Facility (Paul Y. Construction Company Limited) |

Project Manager |

Ken Tang |

9640 5397 |

|

Environmental Officer |

Ferddy Leung |

5585 6746 |

|

|

Contract 3308 Foreign Object Debris Detection System (DAS Aviation Services Group) |

Project Manager |

Jeffrey Yau |

9873 7422 |

|

Contract 3310 North Runway Modification Works (China State Construction Engineering (Hong Kong) Ltd.) |

Project Manager |

Kingsley Chiang |

9424 8437 |

|

Environmental Officer |

Federick Wong |

9842 2703 |

Terminal 2 Concourse and Apron Works:

|

Party |

Position |

Name |

Telephone |

|

Contract 3402 New Integrated Airport Centres Enabling Works (Wing Hing Construction Co., Ltd.) |

Project Manager |

Wyman Lau |

6112 9753 |

|

Health Safety Environmental Manager |

Mike Leung |

6625 2550 |

|

|

Contract 3403 New Integrated Airport Centres Building and Civil Works (Sun Fook Kong Construction Limited) |

Project Manager |

Alice Leung |

9220 3162 |

|

Environmental Officer |

Ray Cheung |

9785 1566 |

|

|

Contract 3404 Integrated Airport Control System (Shun Hing Systems Integration Co., Ltd.) |

Project Manager |

Andy Ng |

9102 2739 |

|

Environmental Officer |

Michael Lo |

6228 3926 |

|

|

Contract 3405 Third Runway Concourse Foundation and Substructure Works (China Road and Bridge Corporation – Bachy Soletanche Group Limited – LT Sambo Co., Ltd. Joint Venture) |

Project Manager |

Francis Choi |

9423 3469 |

|

Environmental Officer |

Jacky Lai |

9028 8975 |

|

|

Contract 3408 Third Runway Concourse and Apron Works (Beijing Urban Construction Group Company Limited and Chevalier (Construction) Company Limited Joint Venture) |

Senior HSE Manager |

Qian Zhang |

5377 7976 |

|

Environmental Officer |

Malcolm Leung |

7073 7559 |

Terminal 2 Expansion:

|

Party |

Position |

Name |

Telephone |

|

Contract 3508 Terminal 2 Expansion Works (Gammon Engineering & Construction Company Limited) |

Project Director |

Richard Ellis |

6201 5637 |

|

Environmental Manager |

Michelle Tang |

9267 8866 |

Automated People Mover and Baggage Handling System:

|

Party |

Position |

Name |

Telephone |

|

Contract 3601 New Automated People Mover System (TRC Line) (CRRC Puzhen Bombardier Transportation Systems Limited and CRRC Nanjing Puzhen Co., Ltd. Joint Venture) |

Project Manager |

Hongdan Wei |

158 6180 9450 |

|

Environmental Officer |

H Y Yue |

9185 8186 |

|

|

Contract 3602 Existing APM System Modification Works (Niigata Transys Co., Ltd.) |

Project Manager |

Xia Bo |

6586 4950 |

|

Environmental Officer |

Y M Tong |

5316 9801 |

|

|

Contract 3603 3RS Baggage Handling System (VISH Consortium) |

Project Manager |

K C Ho |

9272 9626 |

|

Environmental Officer |

Richard Ng |

9802 9577 |

Airport Support Infrastructure:

|

Party |

Position |

Name |

Telephone |

|

Contract 3801 APM and BHS Tunnels on Existing Airport Island (China State Construction Engineering (Hong Kong) Ltd.) |

Project Manager |

Kingsley Chiang |

9424 8437 |

|

Environmental Officer |

Eunice Kwok |

9243 1331 |

|

|

Contract 3802 APM and BHS Tunnels and Related Works (Gammon Engineering & Construction Company Limited) |

Project Director |

John Adams |

6111 6989 |

|

Environmental Officer |

Yan Ng |

5345 8555 |

|

|

Contract 3804 East and Landside Fire Stations (Beijing Urban Construction Group Company Limited - Beijing Urban Construction International Company Limited - Kin Shing (Leung's) General Contractors Ltd Joint Venture) |

Project Manager |

Mr. Zhang Xianda |

4661 6818 |

|

Environmental Officer |

Ms. Kimberly Wong |

5542 1669 |

|

|

Contract 3805 New Airport District Police Operational Base (Chinney Construction Co., Ltd.) |

Project Manager |

Cheuk Wing Wai |

9339 8321 |

|

Environmental Officer |

Mike Li |

6306 8547 |

Construction Support:

|

Party |

Position |

Name |

Telephone |

|

Contract 3721 Construction Support Infrastructure Works (China State Construction Engineering (Hong Kong) Ltd.) |

Senior Project Manager |

Thomas Lui |

9011 5340 |

|

Environmental Officer |

John Mak |

6273 8703 |

|

|

Contract 3728 Minor Site Works (Shun Yuen Construction Company Limited) |

Contract Manager |

C K Liu |

9194 8739 |

|

Environmental Officer |

Dan Leung |

6856 5899 |

|

|

Contract 3733 Emergency Repair Service (Wing Hing Construction Co., Ltd.) |

Project Manager |

Michael Kan |

9206 0550 |

|

Safety Health Environmental Manager |

Mike Leung |

6625 2550 |

|

|

Contract 3901A Concrete Batching Facility (K. Wah Concrete Company Limited) |

Project Manager |

Benedict Wong |

9553 2806 |

|

Environmental Officer |

C P Fung |

9874 2872 |

|

|

Contract 3901B Concrete Batching Facility (Gammon Construction Limited) |

General Manager |

Gabriel Chan |

2435 3260 |

|

Environmental Officer |

Rex Wong |

2695 6319 |

|

|

Contract 3908 Quay Management Services (Gitanes – Crown Asia Joint Venture) |

Project Manager |

Mr. Ian Li |

9750 6438 |

|

Environmental Officer |

Mr. Tang Kai Fun |

9406 3526 |

|

|

Contract 3913 Asphalt Batching Plant (SPR Joint Venture) |

Project Manager |

Xie Yi Sheng |

6580 6005 |

|

Environmental Officer |

Kenneth Chan |

9300 2182 |

|

Utilities: |

|||

|

Party |

Position |

Name |

Telephone |

|

132 kV Cable (CLP Power Hong Kong Limited / Kum Shing (K.F.) Construction Company Limited) |

Engineer |

Ken Fung |

6391 9087 |

|

Project Engineer |

Ivan Shek |

9822 5836 |

|

1.4

Summary of Construction Works

During the reporting period, the project is in the Interim Two-Runway System (I-2RS) stage, in which the new North Runway and the associated taxiway and facilities were operated together with the South Runway and existing airport facilities, with the Centre Runway closed down for modification works.

The key activities of the Project carried out in the reporting period are located in reclamation areas and existing airport island respectively. Works in the reclamation areas included land improvement works, filling works, pavement works, concourse superstructure works, tunnel works for APM and BHS and associated works. Land-based works on existing airport island involved T2 expansion works, modification and tunnel works for APM and BHS, utilities works, road and drainage works, excavation works, and 132kV cable laying works.

The locations of key construction activities are presented in Figure 1.1.

1.5

Summary

of EM&A Programme Requirements

The status for all environmental aspects are presented in Table 1.2. The EM&A requirements remained unchanged during the reporting period.

Table 1.2: Summary of Status of All Environmental Aspects under the Updated EM&A Manual

|

Parameters |

EM&A Requirements |

Status |

|

Air Quality |

||

|

Baseline Monitoring |

At least 14 consecutive days before commencement of construction work |

The baseline air quality monitoring result was reported in Baseline Monitoring Report and submitted to EPD under EP Condition 3.4. |

|

Impact Monitoring |

At least 3 times every 6 days |

On-going |

|

Noise |

||

|

Baseline Monitoring |

Daily for a period of at least two weeks prior to the commencement of construction works |

The baseline noise monitoring result was reported in Baseline Monitoring Report and submitted to EPD under EP Condition 3.4. |

|

Impact Monitoring |

Weekly |

On-going |

|

Water Quality |

||

|

General Baseline Water Quality Monitoring for reclamation, water jetting and field joint works |

Three days per week, at mid-flood and mid-ebb tides, for at least four weeks prior to the commencement of marine works. |

The baseline water quality monitoring result was reported in Baseline Water Quality Monitoring Report and submitted to EPD under EP Condition 3.4. |

|

General Impact Water Quality Monitoring for reclamation, water jetting and field joint works |

Three days per week, at mid-flood and mid-ebb tides. |

General impact water quality monitoring for water jetting works was completed on 23 May 2017. The impact water quality monitoring was terminated after 31 October 2023. |

|

Initial Intensive Deep Cement Mixing (DCM) Water Quality Monitoring |

At least four weeks |

The Initial Intensive DCM Monitoring Report was submitted and approved by EPD in accordance with the Detailed Plan on DCM. |

|

Regular DCM Water Quality Monitoring |

Three times per week until completion of DCM works. |

Due to the completion of all marine-based DCM works within April 2022, regular DCM monitoring was ceased at all monitoring stations starting from 28 April 2022. |

|

Post-construction phase water quality monitoring |

Three days per week, at mid-flood and mid-ebb tides for four weeks |

The four-week post-construction phase water quality monitoring exercise was commenced on 14 November 2023 and completed on 9 December 2023. |

|

Sewerage and Sewage Treatment |

||

|

Methodology for carrying out annual sewage flow monitoring for concerned gravity sewer |

Methodology to be prepared and submitted to EPD one year before the scheduled commencement of operation of the proposed third runway |

The proposed methodology of the annual sewage flow monitoring was approved by EPD. The annual flow monitoring was started from June 2021 and completed in 2022. |

|

Details of the routine H2S monitoring system for the sewerage system of 3RS |

Details to be prepared and submitted to EPD at least one year before commencement of the operation of 3RS |

The H2S monitoring proposal was accepted by EPD in Jun 2023. |

|

Waste Management |

||

|

Waste Monitoring |

At least weekly |

On-going |

|

Land Contamination |

||

|

Supplementary Contamination Assessment Plan (CAP) |

At least 3 months before commencement of any soil remediation works. |

The Supplementary CAP was submitted and approved by EPD under EP Condition 2.20. |

|

Site Re-appraisal Summary Report for Fire Training Facility |

Site Re-appraisal Summary Report for Fire Training Facility |

Site Re-appraisal Summary Report for Fire Training Facility was submitted and accepted by EPD. |

|

Contamination Assessment Report (CAR) for Golf Course |

CAR to be submitted for golf course |

The CAR for Golf Course was submitted and accepted by EPD. |

|

Contamination Assessment Reports (CAR) for Terminal 2 Emergency Power Supply Systems |

CAR to be submitted for Terminal 2 Emergency Power Supply Systems |

The CARs for Terminal 2 Emergency Power Supply Systems were submitted and accepted by EPD. |

|

Terrestrial Ecology |

||

|

Pre-construction Egretry Survey Plan |

Once per month in the breeding season between April and July, prior to the commencement of HDD drilling works. |

The Egretry Survey Plan was submitted and approved by EPD under EP Condition 2.14. |

|

Ecological Monitoring |

Monthly monitoring during the HDD construction works period from August to March. |

The terrestrial ecological monitoring at Sheung Sha Chau was completed in January 2019. |

|

Marine Ecology |

||

|

Pre-Construction Phase Coral Dive Survey |

Prior to marine construction works |

The Coral Translocation Plan was submitted and approved by EPD under EP Condition 2.12. |

|

Coral Translocation |

- |

The coral translocation was completed. |

|

Post-Translocation Coral Monitoring |

As per an enhanced monitoring programme based on the Coral Translocation Plan |

The post-translocation monitoring programme according to the Coral Translocation Plan was completed in April 2018. |

|

Chinese White Dolphins (CWD) |

||

|

Baseline Monitoring |

6 months of baseline surveys before the commencement of land formation related construction works. Vessel line transect surveys: Two full surveys per month; Land-based theodolite tracking surveys: Two days per month at the Sha Chau station and two days per month at the Lung Kwu Chau station; and Passive Acoustic Monitoring (PAM): For the whole duration of baseline period. |

Baseline CWD results were reported in the CWD Baseline Monitoring Report and submitted to EPD in accordance with EP Condition 3.4. |

|

Impact Monitoring |

Vessel line transect surveys: Two full surveys per month; Land-based theodolite tracking surveys: One day per month at the Sha Chau station and one day per month at the Lung Kwu Chau station; and PAM: For the whole duration for land formation related construction works. |

The construction phase CWD monitoring was completed in December 2023. |

|

Post-construction Phase Monitoring |

12 months of post-construction phase CWD monitoring upon the completion of marine construction works. Vessel line transect surveys: Two full surveys per month. |

The post-construction phase CWD monitoring was commenced in January 2024. |

|

Landscape & Visual |

|

|

|

Landscape & Visual Plan |

At least 3 months before the commencement of construction works on the formed land of the Project. |

The Landscape & Visual Plan was submitted and approved by EPD under EP Condition 2.18. |

|

Baseline Monitoring |

One-off survey within the Project site boundary prior to commencement of any construction works |

The baseline landscape & visual monitoring result was reported in Baseline Monitoring Report and submitted to EPD under EP Condition 3.4. |

|

Impact Monitoring |

Weekly |

On-going |

|

Establishment Works Monitoring |

Bi-monthly |

On-going |

|

Long Term Management (10 years) Monitoring |

Annually |

On-going |

|

Environmental Auditing |

|

|

|

Regular site inspection |

Weekly |

On-going |

|

Marine Mammal Watching Plan (MMWP) implementation measures |

Monitor and check |

No Marine Mammal Watching Plan (MMWP) implementation measures during this reporting period. |

|

Dolphin Exclusion Zone (DEZ) Plan implementation measures |

Monitor and check |

No Dolphin Exclusion Zone (DEZ) monitoring was conducted during this reporting period |

|

SkyPier High Speed Ferries (HSF) implementation measures |

Monitor and check |

On-going |

|

Construction and Associated Vessels Implementation measures |

Monitor and check |

On-going |

|

Silt Curtain Deployment Plan implementation measures |

Monitor and check |

Silt Curtain Deployment Plan measures was implemented at C7a during this reporting period. |

|

Spill Response Plan implementation measures |

Monitor and check |

On-going |

|

Complaint Hotline and Email channel |

Construction phase |

On-going |

|

Environmental Log Book |

Construction phase |

On-going |

Taking into account the construction works in this reporting period, impact monitoring of air quality, noise, waste management and landscape & visual were carried out in the reporting period.

The EM&A programme also involved weekly site inspections and related auditing conducted by the ET for checking the implementation of the required environmental mitigation measures recommended in the approved EIA Report. To promote the environmental awareness and enhance the environmental performance of the contractors, regular environmental management meetings were conducted during the reporting period, which are summarised as below:

Eighteen environmental management meetings for EM&A review with works contracts: 9, 10, 11, 18, 19, 22, 23, 24, 26 and 29 April 2024.

The EM&A programme has been following the recommendations presented in the approved EIA Report and the Manual. A summary of implementation status of the environmental mitigation measures for the construction phase of the Project during the reporting period is provided in Appendix A.

2

Air Quality Monitoring

Air quality monitoring of 1-hour Total Suspended Particulates (TSP) was conducted three times every six days at two representative monitoring stations in the vicinity of air sensitive receivers in Tung Chung and villages in North Lantau in accordance with the Manual. Table 2.1 describes the details of the monitoring stations. Figure 2.1 shows the locations of the monitoring stations.

Table 2.1: Locations of Impact Air Quality Monitoring Stations

|

Monitoring Station |

Location |

|

AR1A |

Man Tung Road Park |

|

AR2 |

Village House at Tin Sum |

2.1

Action

and Limit Levels

In accordance with the Manual, baseline air quality monitoring of 1-hour TSP levels at the two air quality monitoring stations were established as presented in the Baseline Monitoring Report. The Action and Limit Levels of the air quality monitoring stipulated in the EM&A programme for triggering the relevant investigation and follow-up procedures under the programme are provided in Table 2.2.

Table 2.2: Action and Limit Levels of Air Quality Monitoring

|

Monitoring Station |

Action Level (mg/m3) |

Limit Level (mg/m3) |

|

AR1A |

306 |

500 |

|

AR2 |

298 |

2.2

Monitoring

Equipment

Portable direct reading dust meter was used to carry out the air quality monitoring. Details of equipment used in the reporting period are given in Table 2.3.

Table 2.3: Air Quality Monitoring Equipment

|

Brand and Model |

Last Calibration Date |

Calibration Certificate Provided in |

|

|

Portable direct reading dust meter (Laser dust monitor) |

SIBATA LD-3B-2 (Serial No. 296098) |

18 Sep 2023 |

Appendix E of Monthly EM&A Report No. 94 |

2.3

Monitoring

Methodology

2.3.1

Measuring

Procedure

The measurement procedures involved in the impact air quality monitoring can be summarised as follows:

a. The portable direct reading dust meter was mounted on a tripod at a height of 1.2m above the ground.

b. Prior to the measurement, the equipment was set up for 1 minute span check and 6 second background check.

c. The one hour dust measurement was started. Site conditions and dust sources at the nearby area were recorded on a record sheet.

d. When the measurement completed, the “Count” reading per hour was recorded for result calculation.

2.3.2

Maintenance

and Calibration

The portable direct reading dust meter is calibrated every year against high volume sampler (HVS) to check the validity and accuracy of the results measured by direct reading method. The calibration record of the HVS provided in Appendix E of the Monthly EM&A Report No. 94 and the calibration certificates of portable direct reading dust meters listed in Table 2.3 are valid in the reporting period.

2.4

Summary

of Monitoring Results

The air quality monitoring schedule of the reporting period is provided in Appendix B.

The air quality monitoring results in the reporting period are summarised in Table 2.4. Detailed impact monitoring results are presented in Appendix C.

Table 2.4: Summary of Air Quality Monitoring Results

|

Monitoring Station |

1-hr TSP Concentration Range (mg/m3) |

Action Level (mg/m3) |

Limit Level (mg/m3) |

|

AR1A |

44 - 97 |

306 |

500 |

|

AR2 |

28 - 125 |

298 |

The monitoring results were within the corresponding Action and Limit Levels at all monitoring stations in the reporting period.

General meteorological conditions throughout the impact monitoring period were recorded. Wind data including wind speed and wind direction for each monitoring day were collected from the Chek Lap Kok Wind Station.

2.5

Conclusion

No dust emission source was observed at the monitoring stations during the monitoring sessions. As the sensitive receivers were far away from the construction activities, with the implementation of dust control measures, there was no adverse impact at the sensitive receivers attributable to the works of the Project.

3

Noise Monitoring

Noise monitoring in the form of 30-minute measurements of Leq, L10, and L90 levels was conducted once per week between 0700 and 1900 on normal weekdays at four representative monitoring stations in the vicinity of noise sensitive receivers in Tung Chung and villages in North Lantau in accordance with the Manual. Table 3.1 describes the details of the monitoring stations. Figure 2.1 shows the locations of the monitoring stations.

Table 3.1: Locations of Impact Noise Monitoring Stations

|

Monitoring Station |

Location |

Type of measurement |

|

NM1A |

Man Tung Road Park |

Free field |

|

NM2(1) |

Tung Chung West Development |

To be determined |

|

NM3A(2) |

Site Office |

Facade |

|

NM4 |

Ching Chung Hau Po Woon Primary School |

Free field |

|

NM5 |

Village House in Tin Sum |

Free field |

|

NM6 |

House No. 1, Sha Lo Wan |

Free field |

Notes:

(1) As described in Section 4.3.3 of the Manual, noise monitoring at NM2 will only commence after occupation of the future Tung Chung West Development.

(2) According to Section 4.3.3 of the Manual, the noise monitoring at NM3A was temporarily suspended starting from 1 September 2018 and would be resumed with the completion of the Tung Chung East Development.

3.1

Action

and Limit Levels

In accordance with the Manual, baseline noise levels at the noise monitoring stations were established as presented in the Baseline Monitoring Report. The Action and Limit Levels of the noise monitoring stipulated in the EM&A programme for triggering the relevant investigation and follow-up procedures under the programme are provided in Table 3.2.

Table 3.2: Action and Limit Levels for Noise Monitoring

|

Monitoring Stations |

Time Period |

Action Level |

Limit Level, Leq(30mins) dB(A) |

|

NM1A, NM2, NM3A, NM4, NM5 and NM6 |

0700-1900 hours on normal weekdays |

When one valid documented complaint is received from any one of the sensitive receivers |

75dB(A)(1) |

Note:

(1) The Limit Level for NM4 is reduced to 70dB(A) for being an educational institution. During school examination period, the Limit Level is further reduced to 65dB(A).

3.2

Monitoring

Equipment

Noise monitoring was performed using sound level meter at each designated monitoring station. The sound level meters deployed comply with the International Electrotechnical Commission Publications 651:1979 (Type 1) and 804:1985 (Type 1) specifications. Acoustic calibrator was used to check the sound level meters by a known sound pressure level for field measurement. Details of equipment used in the reporting period are given in Table 3.3.

Table 3.3: Noise Monitoring Equipment

|

Equipment |

Brand and Model |

Last Calibration Date |

Calibration Certificate Provided in |

|

Integrated Sound Level Meter |

Rion NL-52 (Serial No. 00998505) |

03 Mar 2024 |

Appendix D of Monthly EM&A Report No.99 |

|

Integrated Sound Level Meter |

Rion NL-52 (Serial No. 01287679) |

22 Oct 2023 |

Appendix D of Monthly EM&A Report No.95 |

|

Acoustic Calibrator |

Castle GA607 (Serial No. 040162) |

03 Mar 2024 |

Appendix D of Monthly EM&A Report No.99 |

|

Acoustic Calibrator |

Casella CEL-120 (Serial No. 2383737) |

18 Jun 2023 |

Appendix D of Monthly EM&A Report No.91 |

3.3

Monitoring

Methodology

3.3.1

Monitoring

Procedure

The monitoring procedures involved in the noise monitoring can be summarised as follows:

a. The sound level meter was set on a tripod at least a height of 1.2m above the ground for free-field measurements at monitoring stations NM1A, NM4, NM5 and NM6. A correction of +3dB(A) was applied to the free field measurements.

b. Façade measurements were made at the monitoring station NM3A.

c. Parameters such as frequency weighting, time weighting and measurement time were set.

d. Prior to and after each noise measurement, the meter was calibrated using the acoustic calibrator. If the difference in the calibration level before and after measurement was more than 1dB(A), the measurement would be considered invalid and repeat of noise measurement would be required after re-calibration or repair of the equipment.

e. During the monitoring period, Leq, L10 and L90 were recorded. In addition, site conditions and noise sources were recorded on a record sheet.

f. Noise measurement results, when higher than the baseline monitoring levels, were corrected with reference to the baseline monitoring levels.

g. Observations were recorded when high intrusive noise (e.g. dog barking, helicopter noise) was observed during the monitoring.

3.3.2

Maintenance

and Calibration

The maintenance and calibration procedures are summarised below:

a. The microphone head of the sound level meter was cleaned with soft cloth at regular intervals.

b. The meter and calibrator were sent to the supplier or laboratory accredited under Hong Kong Laboratory Accreditation Scheme (HOKLAS) to check and calibrate at yearly intervals.

Calibration certificates of the sound level meters and acoustic calibrators used in the noise monitoring listed in Table 3.3 are valid in the reporting period.

3.4

Summary

of Monitoring Results

The noise monitoring schedule of reporting period is provided in Appendix B.

The noise monitoring results in the reporting period are summarised in Table 3.4. Detailed impact monitoring results are presented in Appendix C.

Table 3.4: Summary of Construction Noise Monitoring Results

|

Monitoring Station |

Noise Level Range, dB(A) Leq (30mins) |

Limit Level, dB(A) Leq (30mins) |

|

NM1A(1) |

62 - 64 |

75 |

|

NM4(1) (3) |

62 - 66 |

70(2) |

|

NM5(1) (3) |

52 - 56 |

75 |

|

NM6(1) (3) |

62 - 68 |

75 |

Notes:

(1) +3dB(A) Façade correction included;

(2) The limit level will be reduced to 65dB(A) during school examination periods at NM4. No school examination took place during this reporting period.

(3) Some of the noise measurement results were higher than the baseline monitoring levels. In order to reduce the influence of non-Project related noise on the monitoring results, these measurement results were corrected with reference to the baseline monitoring results.

No complaints were received from any sensitive receiver as listed in Table 3.1 that triggered the Action Level. All monitoring results were within the corresponding Limit Levels at all monitoring stations in the reporting period.

3.5

Conclusion

As the construction activities were

far away from the monitoring stations, major sources of noise dominating the

monitoring stations observed during the construction noise impact monitoring

were traffic noise near NM1A, school activities near NM4 and aircraft noise

near NM6 during this reporting period. It is considered that the monitoring

work during the reporting period was effective and there was no adverse impact

attributable to the Project activities.

4

Water Quality Monitoring

The construction phase water quality impact monitoring was carried out according to Section 5.1.8 of the Updated EM&A Manual. With the completion of land formation works including seawall construction and all marine filling works in the first quarter of 2023, termination of the construction phase water quality impact monitoring was proposed to EPD with approval granted on 30 October 2023. The water quality impact monitoring was terminated after 31 October 2023.

A post-construction phase water quality monitoring exercise was carried out for four weeks according to Section 5.1.10.1 of the Updated EM&A Manual, in the same manner as the impact monitoring at all impact monitoring stations, sensitive receivers stations and control stations during construction phase, from 14 November 2023 to 9 December 2023. The comparison between the baseline, construction phase and post-construction phase monitoring results will be presented in the Annual EM&A report for 2023 and Final EM&A report.

5

Waste Management

In accordance with the Manual, the waste generated from construction activities was audited once per week to determine if wastes are being managed in accordance with the Waste Management Plan (WMP) prepared for the Project, contract-specific WMP, and any statutory and contractual requirements. All aspects of waste management including waste generation, storage, transportation and disposal were assessed during the audits.

5.1

Action

and Limit Levels

The Action and Limit Levels of the construction waste are provided in Table 5.1.

Table 5.1: Action and Limit Levels for Construction Waste

|

Monitoring Stations |

Action Level |

Limit Level |

|

Construction Area |

When one valid documented complaint is received |

Non-compliance of the WMP, contract-specific WMPs, any statutory and contractual requirements |

5.2

Waste

Management Status

Weekly monitoring on all works contracts were carried out by the ET to check and monitor the implementation of proper waste management practices during the construction phase.

Recommendations made included provision and maintenance of proper chemical waste storage area, as well as handling, segregation, and regular disposal of general refuse. The contractors have taken actions to implement the recommended measures. Waste management audits were carried out by ET according to the requirement of the Waste Management Plan, Updated EM&A Manual and the implementation schedule of the waste management mitigation measures in Appendix A.

Based on updated contractors’ information, construction waste generated in the reporting period is summarised in Table 5.2. The ET and IEC have carried out site audits regularly and reviewed the trip ticket system. Dedicated areas for sorting of materials are established on site. Recyclable materials such as steel bar, metal strip, aluminium, paper and plastic are sorted on-site and transported off-site for recycling during this reporting period.

Table 5.2: Construction Waste Statistics

|

|

|

C&D Material Stockpiled for Reuse or Recycle(1) (m3) |

C&D Material Reused in the Project (m3) |

C&D Material Reused in other Projects (m3) |

C&D Material Transferred to Public Fill (m3) |

Chemical Waste (kg) |

Chemical Waste (l) |

General Refuse (tonne) |

|

|||||||||||||||||||||

|

Jan 2024(2) |

|

0 |

1,508 |

1,530 |

6,897 |

2,500 |

0 |

4,501 |

||||||||||||||||||||||

|

Feb 2024(2) |

|

0 |

486 |

0 |

5,373 |

0 |

600 |

3,383 |

||||||||||||||||||||||

|

Mar 2024(2) |

|

0 |

137 |

10,381 |

8,814 |

0 |

1,800 |

4,825 |

|

|||||||||||||||||||||

|

Apr 2024(3) |

|

0 |

131 |

0 |

5,012 |

0 |

0 |

4,880 |

||||||||||||||||||||||

|

Notes: (1) C&D refers to Construction and Demolition. (2) Updated figures were provided by contractors. (3) The data was based on the information provided by contractors up to the submission date of this Monthly EM&A Report and might be updated in the forthcoming Monthly EM&A Report. |

|

|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

There were no complaints, non-compliance of the WMP, contract-specific WMPs, statutory and contractual requirements that triggered Action and Limit Levels in the reporting period.

5.3

Marine

Sediment Management

Marine sediment is managed according to the EIA Report, Updated EM&A Manual, Waste Management Plan and the proposal of Further Development on Treatment Level / Details and the Reuse Mode for Marine Sediment (hereinafter referred to as “Further Development Proposal”) of the Project. The storage conditions of the excavated marine sediment, treatment process, final backfilling location as well as associated records were inspected and checked by ET and verified by IEC to ensure they were in compliance with the requirements as stipulated in the Waste Management Plan and Further Development Proposal.

Backfilling works for treated marine sediment was conducted during the reporting period. The details of the marine sediment sampling, treatment and backfilling can be referred to Annual EM&A Report.

6

Chinese White Dolphin Monitoring

In accordance with the Manual, CWD monitoring by small vessel line-transect survey should be conducted during post-construction phase. The small vessel line-transect survey should be conducted at a frequency of two full surveys per month as stipulated in the Manual.

6.1

CWD

Monitoring Transects

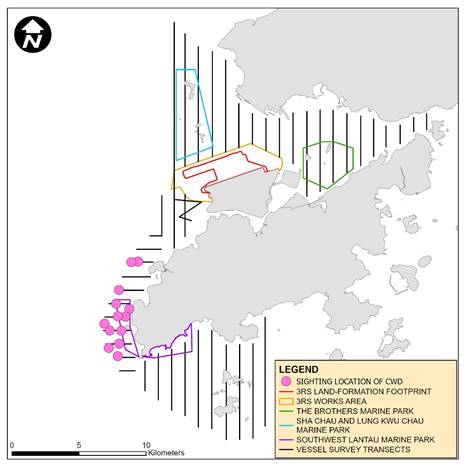

Small vessel line-transect surveys were conducted along the transects covering Northeast Lantau (NEL), Northwest Lantau (NWL), Airport West (AW), West Lantau (WL) and Southwest Lantau (SWL) areas as proposed in the Manual, which are consistent with the Agriculture, Fisheries and Conservation Department (AFCD) long-term monitoring programme (except the addition of AW). The AW transect has not been previously surveyed in the AFCD programme due to the restrictions of HKIA Approach Area, nevertheless, this transect was established during the EIA of the 3RS Project and refined in the Manual with the aim to collect project specific baseline information within the HKIA Approach Area to fill the data gap that was not covered by the AFCD programme. This also provided a larger sample size for estimating the density, abundance and patterns of movements in the broader study area of the project.

The planned vessel survey transect lines for post-construction phase CWD monitoring following the waypoints set for construction phase monitoring as proposed in the Manual are depicted in Figure 6.1 with the waypoint coordinates of all transect lines given in Table 6.1, which are subject to on-site refinement based on the actual survey conditions and constraints.

Table 6.1: Coordinates of Transect Lines in NEL, NWL, AW, WL and SWL Survey Areas

|

Waypoint |

Easting |

Northing |

Waypoint |

Easting |

Northing |

|

NEL |

|||||

|

1S |

813525 |

820900 |

6N |

818568 |

824433 |

|

1N |

813525 |

824657 |

7S |

819532 |

821420 |

|

2S |

814556 |

818449 |

7N |

819532 |

824209 |

|

2N |

814559 |

824768 |

8S |

820451 |

822125 |

|

3S |

815542 |

818807 |

8N |

820451 |

823671 |

|

3N |

815542 |

824882 |

9S |

821504 |

822371 |

|

4S |

816506 |

819480 |

9N |

821504 |

823761 |

|

4N |

816506 |

824859 |

10S |

822513 |

823268 |

|

5S |

817537 |

820220 |

10N |

822513 |

824321 |

|

5N |

817537 |

824613 |

11S |

823477 |

823402 |

|

6S |

818568 |

820735 |

11N |

823477 |

824613 |

|

NWL |

|||||

|

1S |

804671 |

814577 |

5S |

808504 |

821735 |

|

1N |

804671 |

831404 |

5N |

808504 |

828602 |

|

2Sb |

805475 |

815457 |

6S |

809490 |

822075 |

|

2Nb |

805476 |

818571 |

6N |

809490 |

825352 |

|

2Sa |

805476 |

820770 |

7S |

810499 |

822323 |

|

2Na |

805476 |

830562 |

7N |

810499 |

824613 |

|

3S |

806464 |

821033 |

8S |

811508 |

821839 |

|

3N |

806464 |

829598 |

8N |

811508 |

824254 |

|

4S |

807518 |

821395 |

9S |

812516 |

821356 |

|

4N |

807518 |

829230 |

9N |

812516 |

824254 |

|

AW |

|||||

|

1W |

804733 |

818205 |

2W |

805045 |

816912 |

|

1E |

806708 |

818017 |

2E |

805960 |

816633 |

|

WL |

|||||

|

1W |

800600 |

805450 |

7W |

800400 |

811450 |

|

1E |

801760 |

805450 |

7E |

802400 |

811450 |

|

2W |

800300 |

806450 |

8W |

800800 |

812450 |

|

2E |

801750 |

806450 |

8E |

802900 |

812450 |

|

3W |

799600 |

807450 |

9W |

801500 |

813550 |

|

3E |

801500 |

807450 |

9E |

803120 |

813550 |

|

4W |

799400 |

808450 |

10W |

801880 |

814500 |

|

4E |

801430 |

808450 |

10E |

803700 |

814500 |

|

5W |

799500 |

809450 |

11W |

802860 |

815500 |

|

5E |

801300 |

809450 |

12S/11E |

803750 |

815500 |

|

6W |

799800 |

810450 |

12N |

803750 |

818500 |

|

6E |

801400 |

810450 |

|

|

|

|

SWL |

|||||

|

1S |

802494 |

803961 |

6S |

807467 |

801137 |

|

1N |

802494 |

806174 |

6N |

807467 |

808458 |

|

2S |

803489 |

803280 |

7S |

808553 |

800329 |

|

2N |

803489 |

806720 |

7N |

808553 |

807377 |

|

3S |

804484 |

802509 |

8S |

809547 |

800338 |

|

3N |

804484 |

807048 |

8N |

809547 |

807396 |

|

4S |

805478 |

802105 |

9S |

810542 |

800423 |

|

4N |

805478 |

807556 |

9N |

810542 |

807462 |

|

5S |

806473 |

801250 |

10S |

811446 |

801335 |

|

5N |

806473 |

808458 |

10N |

811446 |

809436 |

6.2 CWD Monitoring Methodology

6.2.1

Small

Vessel Line-transect Survey

Small vessel line-transect surveys provided data for density and abundance estimation and other assessments using distance-sampling methodologies, specifically, line-transect methods.

The surveys involved small vessel line-transect data collection and have been designed to be similar to, and consistent with, previous surveys for the AFCD for their long-term monitoring of small cetaceans in Hong Kong. The survey was designed to provide systematic, quantitative measurements of density, abundance and habitat use.

As mentioned in Section 6.1, the transects covered NEL, NWL, AW, WL and SWL areas as proposed in the Manual, which are consistent with the AFCD long-term monitoring programme (except AW). There are two types of transect lines:

Primary transect lines: the parallel and zigzag transect lines as shown in Figure 6.1; and

● Secondary transect lines: transect lines connecting between the primary transect lines and going around islands.

All data collected on both primary and secondary transect lines were used for analysis of sighting distribution, group size, activities including association with fishing boat, and mother-calf pairs. Only on-effort data collected under favourable conditions of Beaufort 0-3 and visibility of approximately 1200 m or beyond were used for analysis of the CWD encounter rates.

A 15-20m vessel with a flying bridge observation platform about 4 to 5m above water level and unobstructed forward view, and a team of three to four observers were deployed to undertake the surveys. Two observers were on search effort at all times when following the transect lines with a constant speed of 7 to 8 knots (i.e. 13 to 15 km per hour), one using 7X handheld binoculars and the other using unaided eyes and recording data.

During on-effort survey periods, the survey team recorded effort data including time, position (waypoints), weather conditions (Beaufort sea state and visibility) and distance travelled in each series with assistance of a handheld GPS device. The GPS device also continuously and automatically logged data including time, position (latitude and longitude) and vessel speed throughout the entire survey.

When CWDs were seen, the survey team was taken off-effort, the dolphins were approached and photographed for photo-ID information (using a Canon 7D [or similar] camera and long 300 mm+ telephoto lens), then followed until they were lost from view. At that point, the boat returned (off effort) to the survey line at the closest point after obtaining photo records of the dolphin group and began to survey on effort again.

Focal follows of dolphins would be used for providing supplementary information only where practicable (i.e. when individual dolphins or small stable groups of dolphins with at least one member that could be readily identifiable with unaided eyes during observations and weather conditions are favourable). These would involve the boat following (at an appropriate distance to minimise disturbance) an identifiable individual dolphin for an extended period of time, and collecting detailed data on its location, behaviour, response to vessels, and associates.

6.2.2

Photo

Identification

CWDs can be identified by their unique features like presence of scratches, nick marks, cuts, wounds, deformities of their dorsal fin and distinguished colouration and spotting patterns.

When CWDs were observed, the survey team was taken off-effort, the dolphins were approached and photographed for photo-ID information (using a Canon 7D [or similar] camera and long 300 mm+ telephoto lens). The survey team attempted to photograph both sides of every single dolphin in the group as the colouration and spotting pattern on both sides may not be identical. The photos were taken at the highest available resolution and stored on Compact Flash memory cards for transferring into a computer.

All photos taken were initially examined to sort out those containing potentially identifiable individuals. These sorted-out images would then be examined in detail and compared to the CWD photo-identification catalogue established for 3RS Project since the baseline monitoring stage.

6.3

Monitoring Results and Observations

6.3.1

Small

Vessel Line-transect Survey

Survey Effort

Within this reporting period, two complete sets of small vessel line-transect surveys were conducted on the 5, 10, 12, 15, 17, 18, 23 and 26 April 2024 covering all transects in NEL, NWL, AW, WL and SWL survey areas for twice.

A total of around 451.30 km of survey effort was collected from these surveys and around 413.86 km survey effort was being conducted under favourable weather condition (i.e. Beaufort Sea State 3 or below with favourable visibility). Details of the survey effort are given in Appendix C.

Sighting Distribution

In the current reporting period, 13 sightings with 43 dolphins were sighted. All these sightings were on-effort records under favourable weather condition (i.e. Beaufort Sea State 3 or below with favourable visibility). Details of dolphin sightings are presented in Appendix C.

Distribution of all CWD sightings recorded in the current reporting period is illustrated in Figure 6.2. All CWD sightings were recorded in WL where most of the CWD sightings was recorded around the waters between Yi O and Fan Lau. There was no CWD sighting recorded in NEL, NWL and SWL during the reporting period.

Figure 6.2: Sightings Distribution of Chinese White Dolphins

Remarks: (1) Please note that there is 13 pink circles on the map indicating the sighting locations of CWDs. (2) Marine park excludes land area and the landward boundary generally follows the high water mark along the coastline.

Group Size

In the current reporting period, 13 groups of 43 dolphins in total were sighted, and the average group size of CWDs was 3.3 dolphins per group. The number of small group size (i.e., 1-2) and median group size (i.e., 3-9) of the CWD sightings are relatively similar and no CWD sighting with large group size (i.e. 10 or more dolphins) was recorded in WL.

Activities and Association with Fishing Boats

There was no CWD sightings recorded engaging in foraging activities in the current reporting period in WL survey areas. No sighting was observed in association with boats.

Mother-calf Pair

In this reporting period, there was one sighting recorded with the presence of mother-and-unspotted juvenile pair(s) recorded in WL.

6.3.2

Photo Identification

In the current reporting period, a total number of 27 different CWD individuals were identified for totally 31 times. A summary of photo identification works is presented in Table 6.2. Representative photos of these individuals are given in Appendix C.

Table 6.2: Summary of Photo Identification

|

Individual ID |

Date of Sighting (dd-mmm-yy) |

Sighting Group No. |

Area |

|

Individual ID |

Date of Sighting (dd-mmm-yy) |

Sighting Group No. |

Area |

|

NLMM012 |

12-Apr-24 |

5 |

WL |

|

WLMM080 |

12-Apr-24 |

1 |

WL |

|

NLMM020 |

12-Apr-24 |

3 |

WL |

|

|

17-Apr-24 |

1 |

WL |

|

SLMM002 |

12-Apr-24 |

9 |

WL |

|

WLMM118 |

12-Apr-24 |

3 |

WL |

|

SLMM023 |

12-Apr-24 |

3 |

WL |

|

WLMM150 |

12-Apr-24 |

9 |

WL |

|

SLMM025 |

12-Apr-24 |

3 |

WL |

|

WLMM152 |

12-Apr-24 |

5 |

WL |

|

SLMM027 |

12-Apr-24 |

3 |

WL |

|

WLMM159 |

17-Apr-24 |

1 |

WL |

|

SLMM029 |

12-Apr-24 |

11 |

WL |

|

WLMM162 |

12-Apr-24 |

12 |

WL |

|

SLMM052 |

12-Apr-24 |

12 |

WL |

|

WLMM163 |

12-Apr-24 |

3 |

WL |

|

SLMM074 |

12-Apr-24 |

7 |

WL |

|

|

|

4 |

WL |

|

WLMM007 |

12-Apr-24 |

9 |

WL |

|

|

|

6 |

WL |

|

WLMM027 |

12-Apr-24 |

4 |

WL |

|

WLMM192 |

12-Apr-24 |

12 |

WL |

|

WLMM039 |

12-Apr-24 |

12 |

WL |

|

WLMM195 |

12-Apr-24 |

2 |

WL |

|

WLMM056 |

12-Apr-24 |

3 |

WL |

|

WLMM196 |

12-Apr-24 |

2 |

WL |

|

|

|

9 |

WL |

|

WLMM197 |

12-Apr-24 |

2 |

WL |

|

WLMM067 |

12-Apr-24 |

12 |

WL |

|

WLMM198 |

12-Apr-24 |

2 |

WL |

|

WLMM068 |

12-Apr-24 |

12 |

WL |

|

|

|

|

|

6.4

Site Audit for CWD-related Mitigation Measures

During the reporting period, no dolphin observation station was deployed by the contractor for continuous monitoring of the DEZ in accordance with the DEZ Plan. During this reporting period, no training session were provided by the ET for the proposed dolphin observers.

Audits of SkyPier high speed ferries route diversion and speed control and construction vessel management are presented in Section 7.4 and Section 7.5 respectively.

6.5

Timing

of reporting CWD Monitoring Results

Detailed analysis of CWD monitoring results collected by small vessel line-transect survey will be provided in upcoming quarterly reports and annual report.

6.6

Summary

of CWD Monitoring

Monitoring of CWD was conducted with two complete sets of small vessel

line-transect surveys. The tentative post-construction phase CWD monitoring

schedule of next reporting month is provided in Appendix B.

7

Environmental Site Inspection and Audit

7.1

Environmental

Site Inspection

Site inspections of the construction works to audit the implementation of proper environmental pollution control and mitigation measures for the Project were conducted by ET and IEC on a weekly and bi-weekly basis, respectively. The weekly site inspection schedule of the construction works is provided in Appendix B. Besides, ad-hoc site inspections were also conducted by ET and IEC if environmental problems were identified, or subsequent to receipt of an environmental complaint, or as part of the investigation work. These site inspections provided a direct means to reinforce the specified environmental protection requirements and pollution control measures in construction sites.

During site inspections, environmental situation, status of implementation of pollution control and mitigation measures were observed. Environmental documents and site records, including waste disposal record, maintenance record of environmental equipment, and relevant environmental permit and licences, were also checked on site. Observations were recorded in the site inspection checklist and passed to the contractor together with the recommended mitigation measures where necessary in order to advise contractors on environmental improvement, awareness and on-site enhancement measures. The observations were made with reference to the following information during the site inspections:

· The EIA and EM&A requirements;

· Relevant environmental protection laws, guidelines, and practice notes;

· The EP conditions and other submissions under the EP;

· Monitoring results of EM&A programme;

· Works progress and programme;

· Proposal of individual works;

· Contract specifications on environmental protection; and

· Previous site inspection results.

Good site practices were observed in site inspections during the reporting period. Advice was given when necessary to ensure the construction workforce were familiar with relevant procedures, and to maintain good environmental performance on site. Regular toolbox talks on environmental issues were organised for the construction workforce by the contractors to ensure understanding and proper implementation of environmental protection and pollution control mitigation measures.

A summary of implementation status of the environmental mitigation measures for the construction phase of the Project during the reporting period is provided in Appendix A.

7.2

Landscape

and Visual Mitigation Measures

Implementation of applicable landscape and visual mitigation measures (reference to the environmental protection measures CM1 – CM10 and OM7 in Appendix A) was monitored in accordance with the Manual. All measures undertaken by both the contractor and the landscape contractor during the construction phase and first year of the operation phase shall be audited by a landscape architect, as a member of the ET, on a regular basis to ensure compliance with the intended aims of the measures. Site inspections shall be undertaken at least once every two months during the operation phase.

The implementation status of the environmental protection measures is summarized below in Table 7.1. Examples of landscape and visual mitigation measures are shown in Table 7.2. The monitoring programme for detailed design, construction, establishment works and long term management (10 years) stages is presented in Table 7.3. Event and Action Plan for Landscape and Visual impacts is stated in Table 7.4.

Table 7.1: Landscape and Visual – Construction Phase Audit Summary

|

Landscape and Visual Mitigation Measures during Construction |

Implementation Status |

Relevant Contract(s) in the Reporting Period |

|

CM1- The construction area and contractor’s temporary works areas shall be minimised to avoid impacts on adjacent landscape. |

The implementation of mitigation measures was checked by ET during weekly site inspection and reported by the Contractors during the monthly Environmental Management Meetings. Implementation of the measures CM5, CM6 and CM7 by Contractors was observed. |

All works contracts |

|

CM2 – Reduction of construction period to practical minimum |

||

|

CM3 – Phasing of the construction stage to reduce visual impacts during the construction phase. |

||

|

CM4 – Construction traffic (land and sea) including construction plants, construction vessels and barges shall be kept to a practical minimum. |

||

|

CM5 – Erection of decorative mesh screens or construction hoardings around works areas in visually unobtrusive colours. |

||

|

CM6 – Avoidance of excessive height and bulk of site buildings and structures |

||

|

CM7 – Control of night-time lighting by hooding all lights and through minimisation of night working periods |

||

|

CM8 – All existing trees shall be carefully protected during construction. Detailed Tree Protection Specification shall be provided in the Contract Specification. Under this specification, the Contractor shall be required to submit, for approval, a detailed working method statement for the protection of trees prior to undertaking any works adjacent to all retained trees, including trees in contractor’s works areas |

Tree Protection Specifications were provided in the relevant Contract Specifications respectively for implementation by the Contractors under the Project.

The Contractors’ performance on the implementation of the tree maintenance and protection measures were observed and checked by the ET weekly during construction period. |

3508 |

|

CM9 – Trees unavoidably affected by the works shall be transplanted where practical. A detailed Tree Transplanting Specification shall be provided in the Contract Specification, if applicable. Sufficient time for necessary tree root and crown preparation periods shall be allowed in the project programme |